Technical Advantages of ZTA Cermet Composite Grinding Roller

CIEIEC specializes in providing customers with best quality cement equipment and spare parts. Here I would like to introduce the technical advantages of ZTA (Zirconia Toughened Alumina) cermet composite grinding roller.

1. Long service life

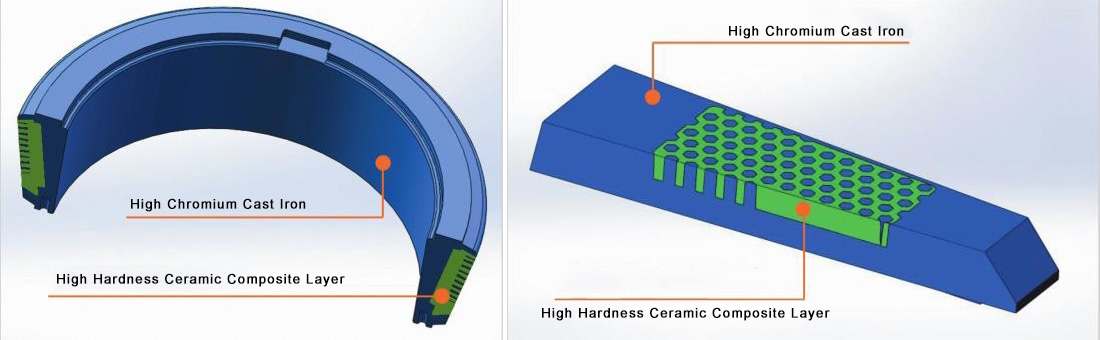

The Vickers hardness of ordinary high chromium cast iron is about 700HV, and the hardness of ZTA (Zirconia Toughened Alumina) ceramics can reach 2100HV. The service life of ZTA cermet composite grinding roller with composite casting technology is 2-3 times of ordinary high chromium cast iron grinding roller.

2. Higher mill working efficiency

The ZTA cermet composite roller sleeve and liner have a special honeycomb ceramic grinding layer design, which increases the friction coefficient between the material ,the original smooth appearance of the roller sleeve and the liner can be better maintained during using life , so that the grinding roller and the liner can better fit and run. The mill has higher working efficiency, which can increase the grinding efficiency by more than 15%.

3. Energy saving

According to user feedback, ZTA cermet composite roller sleeves reduce the unit power consumption of the mill by 1kWh/Ton compared with high chromium cast iron roller sleeves. This is due to the special negative pressure casting infiltration composite casting process of ZTA cermet composites.

4. Reduce the mill maintenance frequency and reduce equipment maintenance cost

Thanks to the great improvement of wear-resistance of the ZTA cermet composite roller sleeve and liner working surface, the number of mill downtime is greatly reduced, and the synchronous maintenance of the mill is realized once every two years, greatly reducing the maintenance workload and equipment maintenance cost.